Bringing in the wool

Cashmere maker charts plan to move up value chain with high-end products

On any given day Times Square in New York is awash with multitudes of billboards and screens that explain the virtues and benefits of several luxury products.

Amid the sea of Western brands and models showcasing various products is a display screen featuring Chinese mode

|

Erdos aims to bring its high-end products to the mainstream fashion market. Provided to China Daily |

Cashmere or "soft gold" or "diamond fiber" has been one of the crown jewels in China's exports and for long a prized item among fashion connoisseurs due to its scarcity and high quality.

The cloudlike wool, derived from long-haired goats, is often spun into yarn and then knitted into sweaters, scarves and shawls, for luxury brands like Hermes Group and Eric Bompard SA.

Starting off as an original equipment manufacturer (OEM) in 1981, Erdos has long been cherishing dreams of coming out with its own range of high-end products.

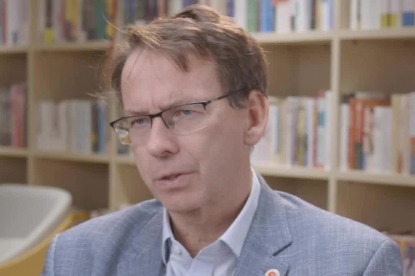

"The Times Square promo will further enhance our high-end image as New York is the high temple of fashion," says Li Changqing, general manager of Erdos Resources Co Ltd, a unit of the Erdos Group that is in charge of the cashmere production.

"Though cashmere makers from Ordos account for more than 40 percent of the global cashmere production, they have not made much headway in the global markets," Li says.

According to the China Textile Association, China is the world's largest exporter of cashmere products, and accounted for nearly 75 percent of the global output in 2011. But nearly 99 percent of the exports were OEM products for foreign brands, and hence did not bring in the kind of returns that most of the companies expected.

But in recent years, the wafer-thin margins of cashmere makers have been further depleted due to rising labor costs and currency fluctuations.

"Last year our annual sales totaled 7.74 billion yuan ($1.22 billion, 930 million euros), half of the sold pieces came from export. But nearly 90 percent of the exports was OEM work for foreign brands. Our overall profit was just 80 million yuan, with domestic sales accounting for the lion's share. This has further reinforced our ambition to move up the value chain with more high-end products," Li says.

"Five years ago, the average salary for a cashmere worker was 1,000 yuan, but has soared to 3,000 yuan this year," he says.

Erdos has already made a head start to move up the value chain by launching the "1436 Erdos" luxury brand in 2007.

|

|

It is not that "1436 Erdos" is looking to attract only foreign customers. Rather, the range was the eyeball-turner at a recent cashmere show in Beijing with its wide range of styles and range of products for various occasions such as office and party wear. Exotic colors not often seen in cashmere sweaters, like orange, pink and purple, received rave enquiries. Cashmere garments were also combined with the elements of silk, fur and embroidery, to further enhance their appeal.

"The '1436 Erdos' has changed people's stereotype that cashmere garments are for the rich, conservative and above-middle-age people. Erdos is now looking to give cashmere a new image by bringing it on to the mainstream fashion market in such a way that it appeals to the younger customers also," Li says.

"Despite the many merits, Chinese cashmere makers often lack vital skills like creativity and marketing," says Li.

To get around the problem, Erdos imported more than 1,150 cashmere garment weaving and testing machines from Germany, with each machine costing more than 400,000 yuan.

The company has also roped in an international team of world famous designers for its brand building such as Gilles Dufour, the former art director of Chanel, and Kevin Yeung, chairman of Hong Kong Designers Association.

"Working in Erdos has been really a fascinating experience. They are hungry for creativity here, and my innovation can be brought into full play," says Gilles Dufour, who was appointed as the design director of Erdos Group in 2008.

Apart from the designers, Erdos also employs more than 2,000 people in design and R&D. It also set up the Erdos Technology Development Center in 1997, the first of its kind in China and the holder of more than 150 national patents.

From 2009, the group has also been investing huge amounts of money to set up a cashmere industrial park, together with the local government, in Ordos in the Inner Mongolia autonomous region. "This will help in the setting up of a complete industrial chain for the cashmere industry," Li says.

The cashmere maker is also looking to grow profits in the lean summer season. "When it is hot in summer, cashmere makers have to face a tough time. To avoid this deadlock, we started to produce summer cashmere clothing in 2000," Li says.

"Our summer range comprises of shirts, made through the combination of cashmere, silk and cotton. Since the main element is light cashmere it makes the shirt softer and comfortable to wear."

Apart from "1436 Erdos", the company also has some other domestically well-known brands such as "Ao Qun". It also has 3,000 franchise stores to sell its brands in the domestic market, and plans to open nearly 600 shops over the next five years, Li says.

Starting off as a textile factory, the Erdos Group now has about 30,000 employees and sales revenue of 7.74 billion yuan from the cashmere business in 2011, a year-on-year increase of 13.8 percent compared with 2010.

"We expect our sales revenue to reach 10 billion yuan from the cashmere industry," Li says.

"We are hopeful that with proper brand promotion, we can achieve the same or even better results than other profitable industries like minerals. For that we also need to have brands that can match up to names like Chanel," Li says.

"We have become a formidable domestic brand in the last 30 years and are confident that we will achieve the same results in the global markets in the next 30 years."

huhaiyan@chinadaily.com.cn

Today's Top News

- Commerce minister urges US to increase areas of cooperation

- Strong demand for China's sovereign bonds signals global confidence

- Ministry urges Japan to 'maintain self-respect'

- Li: Forge closer ties with Zambia

- China seeks follow-up actions on Nexperia

- Xi: Emulate Hu Yaobang's spirit, style