C919 boasts a global sourcing model

China's first homegrown large passenger jet has also made significant breakthroughs

The C919 aircraft, China's first homegrown large passenger jet, boasts a global sourcing model that is similar to that of Boeing Co and Airbus Group SE. The model is believed to increase production efficiency and save costs, but aircraft manufacturers retain control of key technologies.

The C919 plane also has several significant technical breakthroughs. Intense research and development was conducted before production, and it uses a large amount of composite materials.

| A C919 aircraft undergoes checks in Shanghai after a test flight. Yin Liqin / For China Daily |

For instance, 85 percent of its tail section is made from composite materials, according to Commercial Aircraft Corp of China, manufacturer of the C919. In China, the technology to apply composite materials is still in its infancy, and the application requires mold manufacturing, temperature control and other techniques.

Harbin Hafei Industry Co, an aviation manufacturer in Harbin, Heilongjiang province, is mainly responsible for the manufacturing of some parts that use composite materials, including the hatch door for the front landing gear and the main landing gear, and the C919's vertical tail.

"We cooperated with Boeing, Airbus and Embraer before," says Li Wei, deputy chief engineer of the C919 project at Hafei. "The design capabilities, quality system and the supplier management capability of COMAC are in line with international standards, when compared with established aircraft manufacturers."

With more than 100,000 components required for the plane, more than 240 local Chinese companies have served as suppliers and manufacturers. More than 460,000 people have been involved in its research and development, and 37 higher education institutions joined the project, COMAC says.

Once mass production and delivery begins, it is expected to drive the rapid growth of the upstream and downstream industry chains and other high-end manufacturing sectors, such as metal materials, mechanical manufacturing, electronic information and chemistry.

Wu Xingshi, a member of the State Council's large passenger aircraft program's expert advisory committee, says the C919 has applied for airworthiness certificates with the industry's regulator, the Civil Aviation Administration of China, as well as the Europe Aviation Safety Agency, and China aims to accelerate the approval process.

"For the ARJ21, the nation's first domestic commercial regional aircraft, it took about six to seven years of test flights before it received the airworthiness certificate, which was the longest period for commercial aircraft in history," he says.

"The ARJ21 serves as a pioneer in China, and the test flight process of the C919 should be faster and more smooth, until it proves that it can meet the operational requirements for commercial use."

Lin Zhijie, an aviation industry analyst and columnist at Carnoc.com, one of China's largest civil aviation web portals, says China serves as the initiator and host of the C919 project.

He says China is responsible for the original design, assembly and supplier management, and those responsibilities are seen as the key parts of large commercial aircraft manufacturing.

"The capability of producing large commercial aircraft is a critical index to assess the industrial manufacturing and technological strengths of a country," Lin says.

"We don't need to label the C919 as 100 percent made in China. Our aim is to integrate the most advantageous resources and latest technologies, and produce aircraft that will be competitive in the global market."

Despite the promising prospects, Lin says the C919's entry to the market won't occur very soon. It is expected to go into operation between 2020 and 2022, and it ultimately aims to break the global market duopoly of Boeing and Airbus.

zhuwenqian@chinadaily.com.cn

(China Daily European Weekly 06/16/2017 page25)

Today's Top News

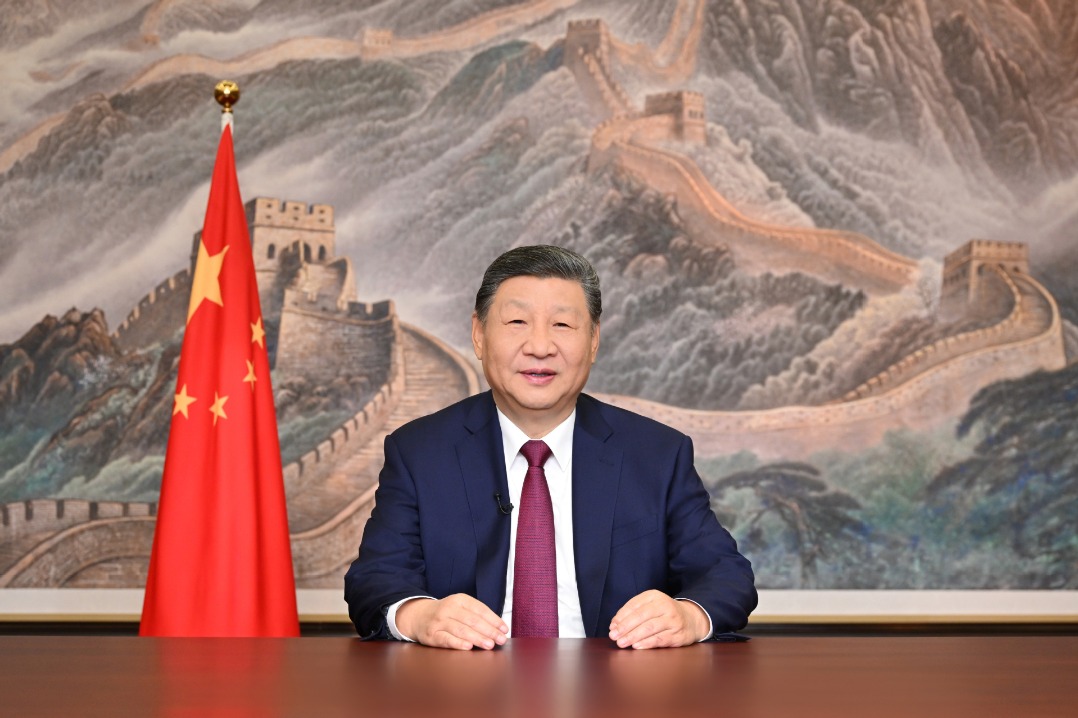

- New Year's address inspiring for all

- Xi congratulates Science and Technology Daily on its 40th anniversary

- Xi congratulates Guy Parmelin on assuming Swiss presidency

- China Daily launches 'China Bound'

- Manufacturing rebounds in December

- PLA wraps up military drills around Taiwan