Machinery on a roll as market rebounds

Tech-savvy Chinese companies ride global boom in construction equipment

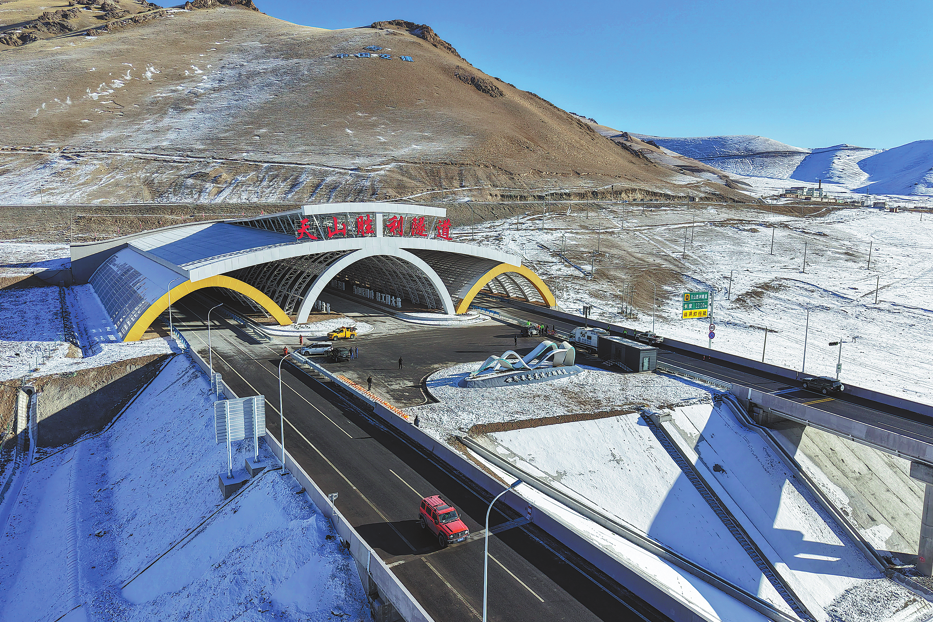

Construction machinery, an industry in which China has a significant presence, is not just used for basic construction nowadays but for advanced projects as well, such as wind power farms, housing for industry workers, development of smart cities and medical equipment factories.

There is increasing demand for excavators, bulldozers, pipe-layers, road rollers and wheel loaders in the countries and regions participating in the Belt and Road Initiative.

| Demand for machinery is growing in China due to nationwide urbanization, new infrastructure projects, industrial upgrading and steady overall economic growth. Provided to China Daily |

Additionally, demand for such machinery is also growing in China itself due to nationwide urbanization, new infrastructure projects, the booming industrial upgrading and steady economic growth overall, experts and business leaders said in the run-up to the 19th National Congress of the Communist Party of China.

"The industry is blossoming, even thriving, thanks to sound economic fundmentals, various key projects and national urbanization campaigns," says Zhang Yongjun, a researcher at the China Center for International Economic Exchanges in Beijing.

New railroad and mining projects; a surging number of works related to environmental protection, agriculture and public service; and public-private partnerships are all using a variety of machines, according to Zhang.

Jim Umpleby, chief executive officer of Caterpillar, the world's largest construction machinery maker, says, "China has vast infrastructure and housing needs.

"And we believe it will remain an important construction equipment market for Caterpillar for the foreseeable future."

In the second quarter of this year, US-based Caterpillar Inc saw sales revenue of $11.3 billion (9.6 billion euros; £8.5 billion), compared with $10.3 billion in the second quarter of 2016, thanks to an increase in construction equipment sales in China, where new infrastructure projects and investment in residential realty boosted sales.

The key industrial segment is expected to see an overall 50 percent year-on-year jump in sales in China to 120,000 units this year.

The sales surge will also be helped by the fact that the sector has entered a fresh replacement cycle after its last peak year in 2011.

The country's ongoing effort to promote the Made in China 2025 strategy is stimulating sales of high-end products, especially those related to informatics industries, in the domestic as well as Belt and Road markets.

This, in turn, is helping the construction machinery sector overcome the quiet market of the past five years, which has kept the available stocks at a low level now, say business leaders.

However, the just-beginning market rebound in China has helped brighten the mood.

For a long time, machinery manufacturers had to deal with problems like production overcapacity, buyers who delayed final payments and stiff environmental standards.

Now, industry discussions focus on rising sales and future prospects.

The excavator branch of the China Construction Machinery Association reported that the country's major construction machinery makers sold 91,400 units in domestic and overseas markets between January and August, up by more than 100 percent year-on-year.

The eight-month sales figure surpassed the full-year number of 70,320 units in 2016. Qi Jun, president of the Beijing-based CCMA, says the excavator segment will likely continue to grow robustly in the second half of this year, given China's ongoing railroad, highway and airport projects in lower-tier cities, as well as urbanization.

Excavator sales have surged since the second half of 2016. The monthly growth rate topped 70 percent year-on-year from September to November last year.

Most companies in the global sector have seen their sales rise robustly, especially major ones such as Sany Heavy Industry Co of China, Liebherr Group of Switzerland and Hitachi Construction Machinery Co of Japan.

Umpleby of Caterpillar says: "Sales in our construction and mining segments are doing well. In fact, we have seen a noticeable uplift in sales of excavators."

The company celebrated the sale of 20,000 mini hydraulic excavators in China in August.

Several factors are responsible for the industry's expectations of a bright future.

The mining industry, which heavily uses construction machinery, is seeing heightened activity due to rising commodity prices.

Zeng Guangan, president of Guangxi Liugong Group, a major Chinese construction machinery maker, says the international price rise for commodities like coal, metals, ferrous metals and nonferrous metals has stimulated sales of excavators and other types of construction machinery, especially in cities such as Tangshan, Hebei province, and Pan zhihua, Sichuan province.

Additionally, a fallout of rising labor costs has seen a shift to smaller machinery.

"The (Chinese) government's ongoing efforts to tackle pollution and build sustainable agricultural and forestry facilities have all saved the industry; and the rise in labor cost will also boost the demand for smaller construction machinery throughout the country," says Zeng.

Technological breakthroughs at home are spurring glad tidings, too. "Domestic machinery manufacturers have made notable technological breakthroughs in terms of product life cycle, durability, new materials and hydraulic technology," says Sun Changjun, vice-president of Hunan province-based Zoomlion Heavy Industry Science and Technology Co.

These achievements will help them to supply products for big-ticket projects like smart cities, nuclear power plants, ultra-high-voltage supply lines, hydroelectric plants and wind power farms.

Such demand is particularly strong in fast-growing markets such as Saudi Arabia, Ethiopia, Kenya, Angola and Brazil.

Chen Bin, executive vice-president of the China Machinery Industry Federation, says Chinese construction machinery makers have already shifted their focus from selling their products to developing markets through dealerships to building after-sales service centers and staff training centers overseas.

For good measure, they are also printing user manuals in French, Portuguese and Russian.

"As many developed countries adopt trade measures to protect their own industries, diversifying market channels in countries and regions participating in the Belt and Road Initiative can help companies ease export pressure," says Chen.

Zhao Chi, secretary-general of the CMIF, says: "Strengthening the dealership network in markets involved in the Belt and Road Initiative can be another effective way to cut financial risk in many emerging markets. Foreign dealers partnering with Chinese companies are familiar with both market environment and customers. They are out to make a profit, and they want a return on their investment as soon as possible."

He says Chinese companies, to be successful, need to build logistics and after-sales service centers in emerging markets, especially in Africa, Southeast Asia and Latin America.

Zhao Ying, a researcher at the Beijing-based Institute of Industrial Economics, which is part of the Chinese Academy of Social Sciences, says that even though more than 80 percent of the domestic market share is held by Chinese manufacturers, foreign companies have already entered China's lower-tier markets through diversified and affordable product categories, customer-friendly dealerships and world-class after-sales service.

For instance, Hitachi's 100-strong team at its plant in Hefei, Anhui province, offers customized services to Chinese clients across the country. This, industry insiders say, helped the Japanese company to build a stronger value chain.

"China's construction machinery producers are gradually losing their low-cost labor advantage and do not yet have the best technologies to lead the industry on a global scale. Chinese companies must act quickly to retain their domestic market lead," says Zhao of the Institute of Industrial Economics.

More than 40,000 machines are currently used on a rental basis. This indicates potential for fast growth of aerial work platforms in the China market, says Yin Xiaoli, deputy secretary-general of the CCMA.

The industry's leading players agree that the size of China's AWP rental fleet will grow tenfold by 2025 as they seek new growth points.

"However, the nature of future competition between large-scale companies and specialized manufacturers, and the division between domestic companies and global brands, is still not clear," Yin says.

Contact the writers at zhongnan@chinadaily.com.cn

(China Daily Africa Weekly 10/20/2017 page26)

Today's Top News

- Civilizational links for a fairer world

- Manufacturing in China spurs global growth

- Taiwan lawmakers vote to pass motion to impeach Lai

- Xi: Steadfastly implement conduct rules

- High-speed rail reaches 50,000 km milestone

- China puts sanctions on US defense firms, execs