Researchers use sunlight to recycle plastic waste

Chinese researchers have made a breakthrough in recycling plastic waste utilizing seawater and sunlight, a process which is low-cost, environmentally friendly and economically viable.

The team at East China Normal University in Shanghai said their process can achieve "closed-loop "recycling of plastic waste and is already attracting huge interest.

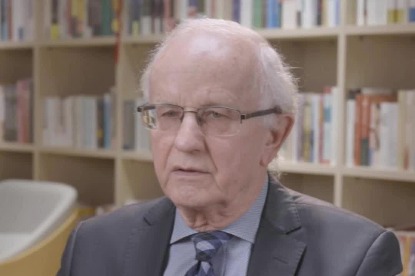

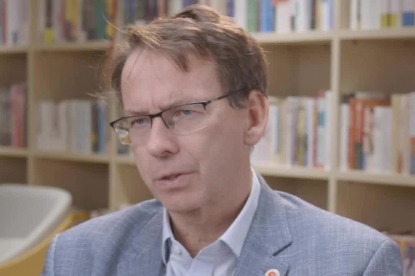

The method, discovered by a research team led by Jiang Xuefeng, a professor at the School of Chemistry and Molecular Engineering at ECNU, uses sunlight to break down the plastics at room temperature, and ambient pressure.

The catalyst used in the process, uranyl cation, is a type of nonradioactive uranium that is abundant in seawater and can be easily extracted.

Jiang said experiments conducted by his team revealed that using uranyl cation and sunlight as an energy source can effectively degrade common plastic waste.

"The entire process is not only environmentally friendly but also energy-saving and highly efficient," he said.

The research team has successfully degraded nine common types of plastic into raw materials, which can be used to produce improved plastics and new ones. It can also be used in other applications such as pharmaceuticals, fragrances and producing materials.

"Previously, the natural decomposition of these plastics would take decades or even centuries," Jiang said.

"But with this method, we can decompose them within a day or two while obtaining commercial chemicals and monomers (molecules that can form polymers) such as benzoic acid and terephthalic acid, which are high-value fine chemicals".

The approach is a breakthrough because it facilitates efficient conversion of plastic bottles to commercial chemicals, highlighting its considerable practical application in closed-loop plastics recycling, Jiang said,

The team's findings were contained in a paper titled "Degradation of Plastic Wastes to Commercial Chemicals and Monomers Under Visible Light", published on July 29 in Science Bulletin, an interdisciplinary science journal jointly sponsored by the Chinese Academy of Sciences and the National Natural Science Foundation of China.

"We aimed to push plastic degradation toward practicality and realism, achieving degradation in complex real-life scenarios," Jiang said.

The process does not require cleaning bottles, he added.

"Having water inside is not a problem. Labels do not need to be removed, and the presence of pigments or adhesives does not affect the process. We have also achieved the degradation of mixed plastics. We aim to turn plastic waste in landfills into valuable, reusable high-purity raw materials."

In their research, Jiang said they were able to achieve degradation of kilogram-scale polyethylene terephthalate (PET) bottles — be they uncleaned, containing water, pigments, adhesives, or additives — with an 88-percent yield of terephthalic acid within two days.

Jiang's research group specializes in sulfur chemistry. They had been exploring a green and energy-saving method to directly oxidize sulfur with sunlight when they found uranyl was an ideal oxidation catalyst that allows precise degradation of plastic wastes.

It took the team more than seven years to refine the method. The researchers are working on expanding the scope of their experiments to include other types of plastics and more mixed plastics scenarios.

Jiang said that since the publication of the paper, he has received requests from both domestic and international sources to cooperate on the industrial application of the method. "I believe we will witness the industrial application of our method within one to two years," Jiang said.

- China opens draft regulations on data protection to public consultation

- Veteran French physicist elected to Chinese Academy of Sciences

- Former Polish deputy PM praises China's economic rise, growing influence

- HK powers the nation's equestrian development

- Forum hailed for promoting Global South modernization

- Wushu needs more events in GBA, coaches in Macao say