Green industry chain driving steel sector

Overall consumption is lower, but pockets of growth have emerged, accompanied by quality improvements

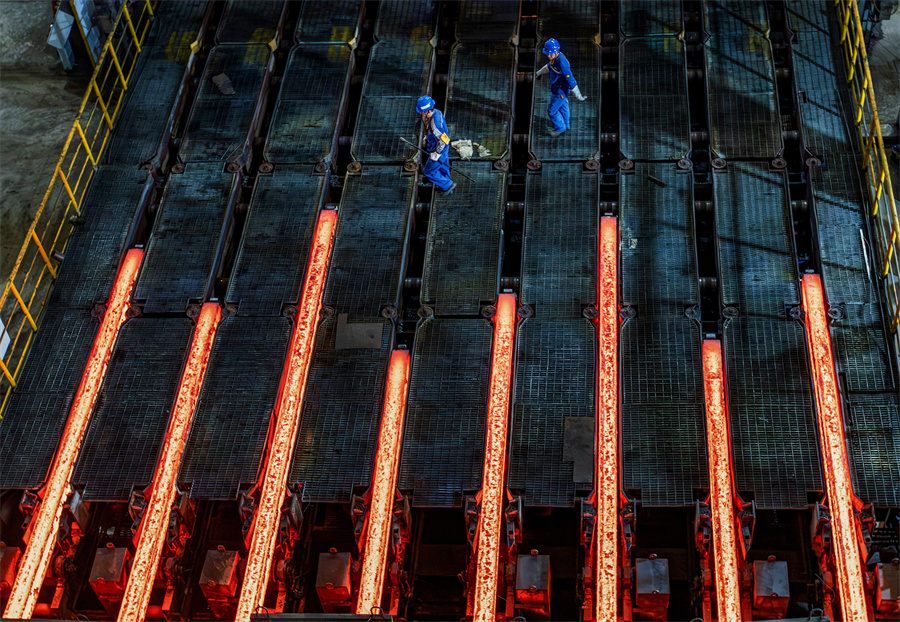

As one enters the gates of Pangang Group Xichang Steel and Vanadium Co Ltd, the steelmaking process is seamless — yet not a single worker is in sight.

The facility is immaculately clean, with every corner reflecting precision and order — offering a glimpse into the cutting-edge efficiency of modern steel plants across China.

China's steel industry has undergone low-carbon transformation and technological upgrades, implementing ultralow emissions retrofits and adjusting its production structure.

This has established a green industrial chain for the steel sector, actively contributing to its high-quality development.

"The industry is currently grappling with lower demand, which underscores the heightened importance of industry self-regulation. Since the beginning of this year (2024), the steel sector has had an obvious transition leading to a phase of reduced output and optimized existing capacity," said Jiang Wei, deputy Party secretary, vice-chairman, and secretary-general of the China Iron and Steel Association.

While overall steel consumption is trending downward, pockets of growth have emerged, accompanied by quality improvements in areas of expansion.

"Demand for steel in construction is declining, but is expected to see marginal improvement, and manufacturing has emerged as the primary driver of steel demand, with rapid growth in industries such as new energy, high-end equipment manufacturing and photovoltaics, significantly boosting demand for specific steel categories," Jiang said.

The share of steel demand from manufacturing is expected to increase further in the future, Jiang added.

In the first three quarters, China produced a total of 768 million metric tons of crude steel, a decrease of 3.6 percent year-on-year. The production of pig iron totaled 644 million tons, down 4.6 percent, and steel production reached 1.044 billion tons, a slight decline of 0.1 percent, said the CISA.

In 2023, the manufacturing and construction accounted for 48 percent and 52 percent of steel demand, respectively.

"It is projected that in 2024, the two sectors will share the market equally, with the share of steel demand from manufacturing potentially increasing even further," Jiang said.

Baoshan Iron and Steel Co Ltd has adjusted and optimized its steel product offerings to align with the evolving demands and trends of emerging manufacturing industries.

Electrical steel, also known as silicon steel, is one of Baosteel's strategic priorities. Since last year, the sector has undergone notable changes on the supply side, maintaining an overall growth trajectory, albeit at a slower pace, the company said.

The supply of grain-oriented silicon steel increased by over 20 percent year-on-year in 2023, but its growth rate slowed to around 5 percent in the first half of 2024. In contrast, the supply of non-oriented silicon steel maintained a steady growth rate of approximately 6 percent during the same period.

From a demand perspective, oriented silicon steel has maintained growth, driven primarily by the expansion of power grids, the construction of ultrahigh voltage transmission lines fueled by the development of renewable energy, and the growing energy storage market, said the company.

The growing popularity of new energy vehicles and the rapid expansion of charging infrastructure are reshaping the steel market, and these trends are fueling demand for materials tailored to energy systems, while the surging need for artificial intelligence computing power further amplifies this shift, said a company executive during a public briefing.

As for non-oriented silicon steel, policies encouraging appliance upgrades and the boom in NEV sales have provided additional momentum for the steel sector and the rise of the low-altitude economy has added a unique twist, sparking demand for ultrathin steel products, he said.