Exploring 'no man's zone'of glass-making science

Skilled engineering, innovation come together to reimagine key material

When China's foldable smartphones began surviving over a million folds without cracking, the spotlight fell on flashy consumer tech. But behind these feats is something far more fundamental: glass.

At the center of this quiet revolution is Bengbu Design and Research Institute for Glass Industry Co Ltd, a core subsidiary of State-owned China National Building Material Group Co Ltd.

Nestled in Bengbu, Anhui province, the institute has emerged as China's champion in high-performance glass, which transforms one of the oldest materials into one of its most advanced.

Liu Aili, a staffer of CNBM's Bengbu Design and Research Institute for Glass Industry Co Ltd, said that the institute has successfully developed a transparent strip of glass barely thicker than a strand of hair.

"The 30-micron flexible glass developed by the institute is the only one in the world that can be mass-produced. It can be bent over a million times without breaking," said Liu. "If you folded it 100 times a day, it would last over 27 years."

Such a feat is astonishing, not only for its engineering, but as it represents a dramatic reimagining of what glass can do and how far China's material science has come, industry experts said.

In 2018, the institute produced the world's thinnest electronic touch glass at just 0.12 millimeters, thinner than a sheet of paper and capable of shattering a long-standing monopoly by foreign suppliers.

That milestone marked a turning point for the Chinese glass industry, shifting it from follower to front-runner.

"The R&D on glass is like a marathon," said Cao Xin, deputy director of the State key laboratory for advanced glass materials, operated by the institute. "Turning something rigid into something flexible is not just a material change, it's an entire chain of innovation."

According to Cao, that chain runs deep, from structural redesign at the molecular level, to new chemical thinning and strengthening processes, to cutting-edge manufacturing equipment developed in parallel.

Each advance, Cao noted, meant solving microscopic problems under macroscopic pressure. "We had to improve defect tolerance by 10 to 20 times, surface flatness by over 10 times — and every micron of progress was hard-won."

In 2020, after countless trials, the institute succeeded in producing its signature 30-micron glass — building an entirely domestic, end-to-end supply chain to make it at scale.

Beyond foldable phones, the institute has quietly been building a catalog of what it calls "black technologies" — deep-tech innovations that quietly power the cutting edge.

For instance, hollow glass microspheres that help deep-sea probes rise from the ocean floor, cadmium telluride solar glass that can harvest power even under dim indoor light, and borosilicate tubes that safely store vaccines.

These innovations aren't just lab curiosities. They're already in use across sectors ranging from clean energy and aerospace to semiconductors and biomedicine.

In late 2024, the world's first 8.6-generation ultra-thin OLED float glass substrate rolled off the production line in Bengbu — once again placing China at the forefront of display materials technology.

Looking ahead, the institute has no intention of slowing down.

Liu said: "We're still exploring the 'no man's zone' of glass science. There are entire frontiers we haven't reached — in flexible electronics, aerospace-grade materials, and smart energy."

From thousands of experiments in the lab to precise calibrations on the production line to stunning product reveals globally, the journey of a single sheet of glass in Bengbu mirrors something larger.

Industry experts said that China's high-stakes pursuit of innovation, and its ability to stretch limits, both literally and metaphorically, highlight the enormous potential of what its industries can achieve.

As Liu put it: "What we're doing here isn't just bending glass. We're bending the future."

Today's Top News

- US scholar: China's 15th Five-Year Plan a blueprint for innovation, welfare, global engagement

- Coding the law for smart governance

- China ready to take tougher steps over Takaichi remarks

- Mobile judicial teams ensure justice for all

- Historic cross-boundary marathon marks a milestone

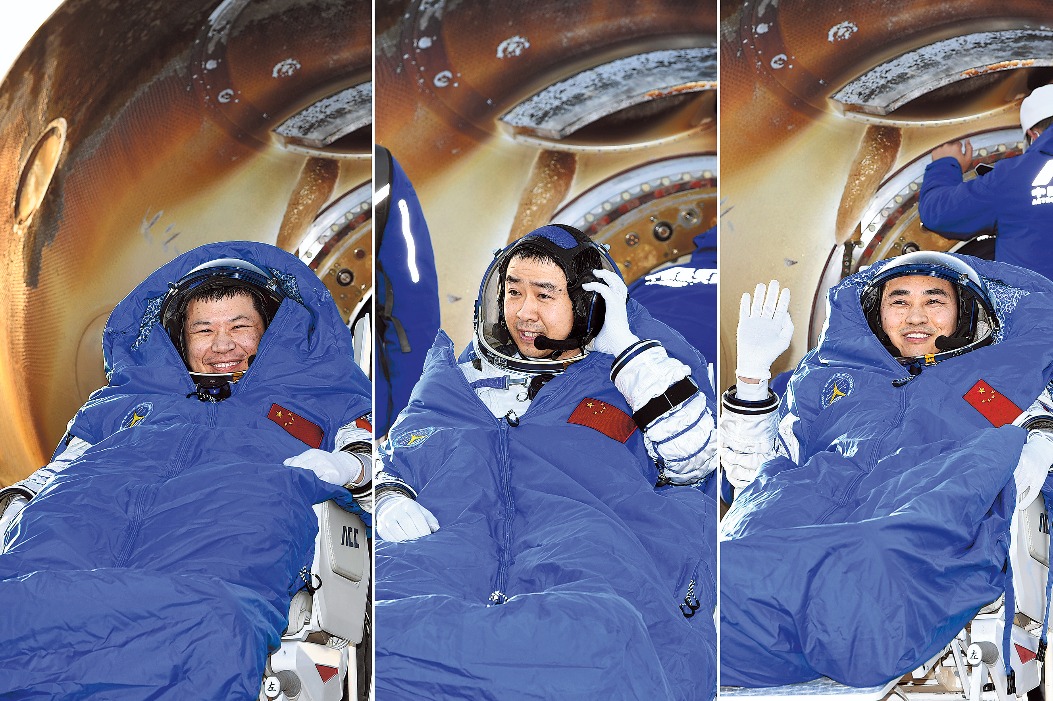

- Preparations begin for new space mission