Yangtze River sees new engineering marvel

After six years of construction, the Changtai Yangtze River Bridge, which has set several world records, officially opened on Tuesday in Jiangsu province.

Spanning 10.03 kilometers, the bridge is the first crossing over the Yangtze River to integrate expressways, intercity railways and regular highways. It connects Changzhou and Taizhou, cutting travel time between the two cities from 1 hour and 20 minutes to about 20 minutes.

The bridge has set various world records. It is the longest-span cable-stayed bridge, the longest-span combined road-rail steel truss arch bridge and has the longest continuous length of steel truss girders. In addition, several world-first technologies were used during construction.

The bridge features a main span of 1,208 meters and two side spans of 388 meters. Its towers stand 350 meters tall — equivalent to a 120-story building.

"This is truly a world-class project," said Li Zhen, onsite commander of the construction command for the Jiangsu provincial transportation engineering construction bureau.

Li said the main span was designed to minimize impact on the Yangtze River's ecological environment and navigation routes.

According to him, the bridge's completion depended on four pioneering designs: a step-type caisson foundation to reduce scouring and self-weight; a steel-concrete hybrid structure with a spatial diamond-shaped tower; a steel-box-core concrete composite cable tower anchorage structure; and a temperature-adaptive longitudinal restraint system for the towerbeam.

For the first time, carbon fiber tendons — which are less affected by temperature changes — were used to create lightweight, high-strength, ultra-long composite material cables, marking a breakthrough in the application of new materials in bridge engineering.

The bridge supports a load capacity of 530,000 metric tons, with two main towers and stay cables providing structural support.

Li likened the towers to human legs, with their stability and strength depending on the underwater caisson.

Initial design calculations indicated the caisson needed to sink more than 65 meters deep to stabilize. But deeper foundations increase construction risks. Technology developed during construction reduced the caisson's height while ensuring stability.

"Even after these adjustments, the caisson remains a massive structure, equivalent to a 24-story building with the length of 13 basketball courts," Li said.

Positioning the caisson was highly challenging, he added.

"During operations, the team employed the latest intelligent robots for the first time. These robots could navigate complex underwater terrains and clean sand from the caisson's corners," he said, noting tasks once reliant on divers can now be completed remotely.

China Railway Baoji Bridge Group, the construction company, also developed several pioneering technologies.

"By introducing large-scale automated production equipment clusters, 3D laser scanning inspection systems, intelligent manufacturing processes and micro-innovations, we successfully overcame the high-standard quality control challenges of large bridges," said Ma Zenggang, project manager at the group.

The bridge passed its load test — considered its final exam — with 110 heavy trucks totaling 4,400 tons, demonstrating its structural integrity.

Jiangsu has now completed 20 river-crossing passages and has nine more under construction, effectively connecting counties and cities across the Yangtze.

Today's Top News

- Spanish king on first state visit to China

- Japan must stop playing with fire on the Taiwan question: China Daily editorial

- The one who tied knot must untie it: China Daily editorial

- Xi congratulates Ouattara on re-election as president of Cote d'Ivoire

- Supercarrier to be put through paces

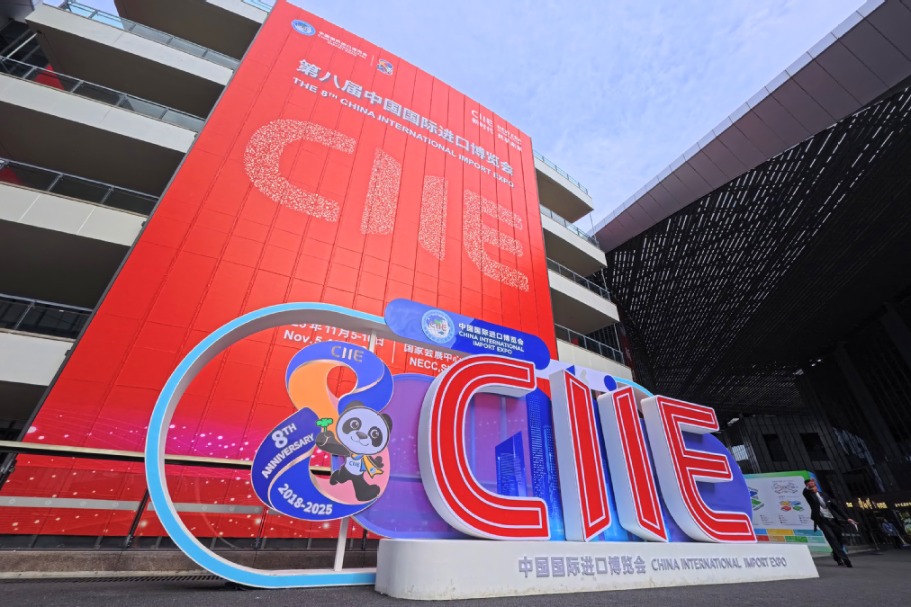

- Game changers for China's sports industry