New era dawns on iron & steel industry

By Zhang Yu (China Daily)Updated: 2007-05-30 09:17

The iron and steel (I&S) industry has been viewed as China's economic lifeline since the planned economy era. For 50 years, China has mass produced I&S, so much so that it became the world's biggest steel producer in 1996.

But a new era has begun in the I&S industry, where more is less, and less is more.

Simply put, if the I&S industry improves technology, it will consume less material and emit less pollution. And if it manages to reduce waste, it will increase its global competitiveness.

That was the decision made at a meeting of the State Council, the Chinese Cabinet, in late April, where officials set the target of eliminating 30 million tons of iron and 35 million tons of steel this year of what they called "backward" production capacity.

The "backward" capacity is to be phased out through mergers and acquisitions (M&A).

The ultimate objective is to eliminate 100 million tons of iron and 55 million tons of steel from annual production capacity before 2010, according to the central government decision.

This is the first time the central government has met to specifically discuss I&S production capacity. According to industry experts, the decision is a green light for the Chinese I&S companies, most of which are already listed, to raise new money on capital markets by flagging their M&A plans for the next year and a half.

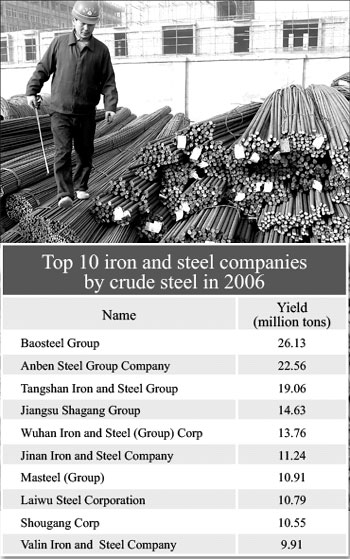

Government support, as decided at the State Council, will focus on the few largest I&S corporations, in hopes of bringing their number from 10 to five or six.

The target set for 2010 also includes lowering the industry's energy use from 760 kilograms of standard coal per ton of output, as reported in 2005, to 730 kilograms, as well as reducing freshwater usage from 12 tons to 6 tons.

Through mergers and acquisitions, China will have "two or three" I&S corporations with 30 million or more tons of annual production capacity, and a string of companies with more than 10 million tons, according to information released by the State Council.

Last year, China produced 420 million tons and consumed 384 tons of iron and steel, ranking first in the world for 11 years in a row.

China has developed its I&S industry by leaps and bounds since the economy opened up in the late 1970s. Because the emphasis has been placed on mass production, the industry became a culprit of high energy use and pollution discharge.

While the industry's output accounted for 3.14 percent of the nation's GDP (gross domestic product), it also claimed 15 percent of the nation's total energy consumption and discharged 10 percent of China's total industrial wastewater, 15 percent of its total industrial dust and 10 percent of its sulphur dioxide emissions.

According to Vice-Premier Zeng Peiyan at the State Council meeting: "If China can manage to dispose of its outdated I&S production capacity, it can save, each year, 50 million tons of standard coal and 100 million tons of freshwater, while reducing at least 400,000 tons of sulphur dioxide emission."

Even worse, most of China's I&S companies are located close to densely populated cities. Some are areas prone to water shortages or major scenic attractions, causing negative impact on the human living environment.

According to China's 11th Five Year Plan, between 2006 and 2010 the nation

will have to cut its energy consumption per unit of GDP by 20 percent and its

pollution discharge by 10 percent.

| 1 | 2 |  |

(For more biz stories, please visit Industry Updates)