|

|

|

OLD TO NEW: A worker from the Shanghai Baosteel Group Corp dismantles a blast furnace on Sept 18, 2013. [Photo/bjreview.com.cn] |

To achieve healthy and efficient economic growth, China must tackle overcapacity

Chimneys and blast furnaces spew out gray, white and dark yellow smog smelling of sulfur, a common scene in Tangshan, North China's Hebei province, a city known for iron and steel manufacturing. There seems to be no end in sight to their numbers, and blackened skies have become the norm, an outcome of over-expansion in China's iron and steel industry.

In recent years, excess production capacity has been spreading, greatly hindering China's economy and posing a severe challenge to its natural environment.

On Oct 15, the State Council issued the Guidelines to Tackle Serious Production Overcapacity, which listed five sectors with severe overcapacity — cement, electrolytic aluminum, sheet glass, shipping and steel — and claiming that such excess would lead to a drop in revenues and mounting risks.

According to statistics, by the end of 2012, the rate of capacity being used up for the five sectors are 72 percent, 73.7 percent, 71.9 percent, 75 percent and 73.1 percent, respectively, which means 25 percent to 28 percent of capacity remains idle. Despite the fact that profits in these sectors have been on the decline, an array of projects remain under construction, aggravating current overcapacity.

Among them, the steel sector is most critical and must cut 80 million tons out of its capacity in the next five years, according to the guidelines.

The culprits

In the eyes of local governments, iron and steel companies have been the major contributors to tax revenue and GDP, so much so that some factories were even allowed to operate without production licenses.

"Almost half of existing steel capacity out there has not yet been officially approved," said Zou Zhongchen, former President of Shandong Iron and Steel Group. A 1-million-ton steel factory can pay taxes as much as 300-500 million yuan ($49.3 million-82.2 million), equivalent to the fiscal revenue of an average county. "How can a local government make up the gap if one such factory is shut down," Zou noted.

Li Xiao, an analyst from Xinhu Futures, believed there were three incentives behind the current steel overcapacity. First, local governments are not willing to sacrifice jobs for capacity reduction. Second, shutting down blast furnaces mean more losses. "Even if a company stops production, it has to pay wages and depreciation costs," Li added. Finally, since steel companies have to borrow money from banks to ensure a cash flow and regular output, production suspension would force banks to end lending, and the capital chains of steel firms would break down.

Miao Changxing, deputy director general at the Ministry of Industry and Information Technology, argued that over optimistic market expectations and blind investment should also be blamed for the oversupply. The profit margin of the steel industry once exceeded 20 percent, which, along with subsidies, tax credits and preferential land policies, boosted overall steel capacity from 300 million tons in 2003 to roughly 1 billion tons in 2012, said Chen Kexin, an expert from Beijing Lange Steel Information Research Center.

Effects

This year, some areas in north and east China have been continuously choked in dense smog. A survey by the Ministry of Environmental Protection showed that 17 out of 20 cities that suffered the most severely polluted air are abound with steel producing factories. When capacity exceeds demand in these areas, not only is the environment harmed, but so is industrial development. In other words, overcapacity impedes China's ability to shift its economy toward more high quality and efficient growth.

World's first 1-liter car debuts in Beijing

World's first 1-liter car debuts in Beijing

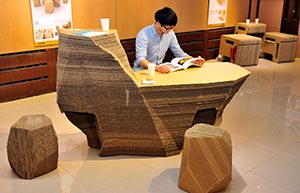

Paper-made furniture lights up art show

Paper-made furniture lights up art show

Robots kick off football match in Hefei

Robots kick off football match in Hefei

Aerobatic team prepare for Aviation Convention

Aerobatic team prepare for Aviation Convention

China Suzhou Electronic Manufacturer Exposition kicks off

China Suzhou Electronic Manufacturer Exposition kicks off

'Squid beauty' and her profitable BBQ store

'Squid beauty' and her profitable BBQ store

A day in the life of a car model

A day in the life of a car model

Vintage cars gather in downtown Beijing

Vintage cars gather in downtown Beijing