To meet its commitment to a greener economy, China's central government has urged all industries to adopt cleaner technologies and reduce greenhouse gas emissions.

The building material sector is no exception.

As the concept of "green building" material spreads, China's industry has ramped up in recent years to develop a recycling economy and improve energy efficiency.

China consumed huge amounts of building materials in its nationwide infrastructure construction over the years, with the booming real estate market promoting consumption as well. Under the government's 4 trillion yuan economic stimulus package to fight the international financial crisis, infrastructure construction is a major investment target, which is expected to spur demand for building materials, especially cement.

Besides domestic consumption, China is also a major global building material exporter. Of all the cement, flat glass and construction ceramic consumed worldwide, about half is produced in China. The nation's building material exports surpassed $18 billion in 2008, 18.4 percent higher than the previous year.

Under such circumstances, progress in the industry to save energy and reduce emissions plays an important role in the country's drive toward a resource conserving, environmentally friendly society.

Even with China's investment-powered growth model and its determination to ensure 8 percent economic growth this year, analysts said little of the government's stimulus spending is allocated to high-energy consuming or highly polluting projects, while spending on environmental segments has increased.

In early May, the National Development and Reform Commission required decommissioning of outdated facilities and restraint on new highly polluting and energy consuming industries - requirements China's building material industry has vowed to meet.

The energy-intensive cement manufacturing sector, the largest in China's building material industry, has been since 1985 the highest producer in the world, accounting for 48 percent of annual global output. China produced 429 million tons of cement in the first four months of this year, up 10.2 percent from the same period last year, with production in April alone rising 10.8 percent to 147 million tons, the biggest growth since last August.

The sector consumes 15 percent of all the coal burned in China and produces 30 percent of dust emissions in all industrial sectors. It also emits 20 percent and 2.6 percent of China's carbon dioxide and sulfur dioxide respectively.

Many provinces, municipalities and regions have now promised to eliminate outdated cement production:

Chongqing municipality plans to cut 10 million tons of low-efficiency production by the end of 2012.

Gansu province has proposed to strengthen restrictions on high energy use, water consumption and highly polluting industries, striving to eliminate 3.75 million tons of outdated capacity in steelmaking, cement manufacturing and papermaking industries in 2009.

Shandong province reduced outdated cement production capacity by 15.85 million tons in 2008, far beyond the central government's designated amount.

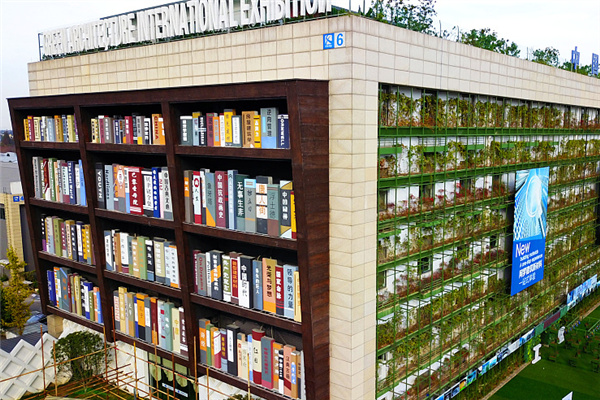

Leading building material enterprises with advanced technologies such as China National Building Material Group Corp, BBMG Corporation and Shandong Shanshui Cement Group Co Ltd, have enabled rapid development of China's building material industry and a number of landmark buildings have been completed. The Bird's Nest, the Water Cube and the National Theater were constructed with building materials supplied by Chinese suppliers.

About 60 listed building material enterprises have raised over 50 billion yuan on the Shanghai and Shenzhen stock exchanges, greatly boosting the companies' self-development and restructuring.

The State-owned China National Building Material Group Corp is China's largest integrated building materials industry group. The group has made impressive strides in pushing the building material industry into a low input, low consumption, low emission and highly energy efficient way through technological innovation, upgrading and industrial structure adjustments.

The Chinese government has vowed to reduce the country's energy consumption by 20 percent per 1,000 yuan of GDP from its 2005 levels during the 11th Five-Year Plan period (2006-2010). And chemical oxygen demand, a key index of water pollution, and emissions of sulfur dioxide, a main air pollutant, will be cut by 10 percent

China's building material industry still has a long way to go to realize these green goals, analysts say, as it involves a wide range of factors, including the implementation of related policies, laws and regulations and improvement of technology and equipment levels. Only by optimizing the industry's product and technology structure and enterprise organization structure, can China's building material industry stay on the green road.

The author is a senior engineer for municipal management and member of advisory team at the State Council Counter-Emergency Office. All views expressed in the article are his own

(China Daily 06/08/2009 page3)