3-D printing adds wings to aviation

Special printers used to produce objects by following a computer blueprint in 'additive manufacturing', Cheng Yingqi reports.

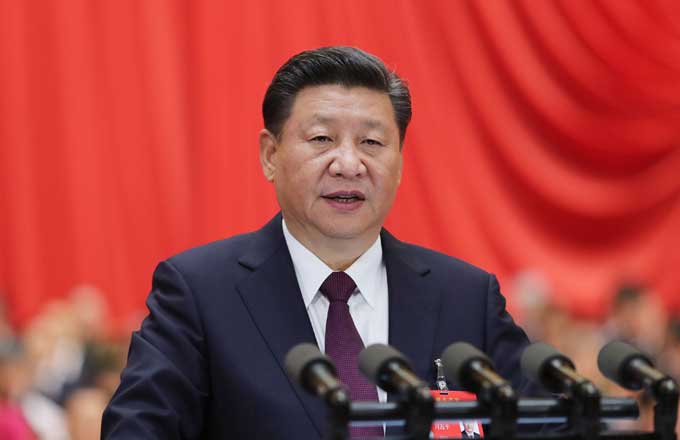

A new industrial process is taking off in the Chinese aviation industry as scientists and industrialists exploit its advantages in the research and manufacture of commercial and military aircraft.

Industry sources said 3-D printing technology has found its way into the production of titanium alloy airframes, landing gear and engine parts, such as turbine blades and disks.

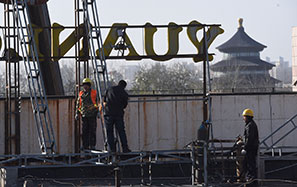

On the C919, China's first domestically designed commercial aircraft, scientists used 3-D printing technologies to design the plane and are now actively exploring production techniques.

The C919 is a narrow-body airliner being built by the Commercial Aircraft Corporation of China.

Industry experts expect the plane, which will have seating for 158 to 174 passengers, to be China's answer to the Boeing 737 and the Airbus A320.

The 3-D design process means the aircraft may burn 12 to 15 percent less fuel than its foreign peers and could reduce operating costs by 10 percent.

In addition to the C919, 3-D printing technology has been used in the manufacture of parts for COMAC's Advanced Jet 21 regional jet, which has been making trial flights since 2009, according to the Beijing-based China Aviation News.

Xi'an Aircraft Industry (Group) Co has established a team to conduct research into the application of 3-D printing techniques in precision casting, which has helped accelerate the development cycle, the paper said.

|

3-D printing development may be 'problematic' Although its application in the technology sector has given 3-D printing a high profile, a number of Chinese entrepreneurs and investors have expressed a pessimistic view of its likely development in the near future. "Some people have said that 3-D printing will bring about a manufacturing revolution, but that's an exaggeration," said Ru Fangjun, founder of HangZhou Xundian Technology Co, which deals in 3-D printing devices in Hangzhou, Zhejiang province |

Also called "additive manufacturing", the process uses special printers to produce a 3-D object by following a computer blueprint. Essentially, the digitized information is fed into a computer, which then controls printer nozzles and sprays layer upon layer of the raw material onto a manufacturing bed to produce a three-dimensional representation of the information. The materials are then fused to create the finished product.

While conventional techniques may take weeks to produce a single component, 3-D printing can complete the task much more quickly.

"With 3-D printing technology, you can produce sophisticated aviation industry components in just half the time and at half the expense of traditional manufacturing methods," said Lu Bingheng, a member of the Chinese Academy of Engineering and a leading light in the field of machinery manufacture and automation.

"As the C919 is still under development, the technology remains scientific exploration. More research should be conducted to ensure the quality of civil aircraft, and we should be able to design a full set of quality standards for the 3-D-printed parts before they are used in commercial applications," Lu said.

Registration Number: 130349