Innovation not imitation

China should solve its own problems, not look to others for the answers

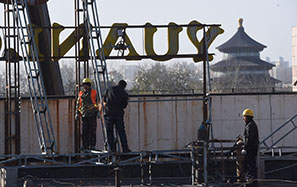

Made in China 2025 - the roadmap for the first 10 years of a national 30-year manufacturing industry strategy - has attracted intense attention in China in the past months.

It implies that not only more people realize the industry is the backbone of the economy, but also that Chinese manufacturing is at the critical tipping point leading to serious crises involving internal manufacturing systems and their external environmental impact.

With the whole nation eager to find potential solutions, Made in China 2025, a comprehensive strategy, has emerged and understandably led to high expectations and extensive media coverage.

More interestingly, during its launch phase, the roadmap has been mentioned by media and some policymakers alongside Germany's Industry 4.0, a manufacturing paradigm with smart factories and intelligent infrastructures defined by the government, engineers and industrialists.

The question must be whether intelligent manufacturing can really save Chinese industrialization and transform the economy and society. Can Industry 4.0 be a universal solution that helps China solve its current and future problems? And do we fundamentally understand the root causes of our manufacturing problems?

There are many reasons why Chinese people, especially with mechanical and manufacturing engineering backgrounds, admire German industrial systems. Their products, processes, designs and philosophies are globally remarkable and almost completely contrary to the Chinese systems.

More importantly, Industry 4.0 has been marketed successfully by highlighting it as a completely new industry paradigm from previous generations. This, coincidently, matched with the typical Chinese mindset favoring revolutionary transformations rather than incremental improvements and continuous hard work.

The Chinese people are scared to lose any opportunity for expansion and improvement. Although Industry 4.0 is an extension or integration of automation systems for the 1980s, information technologies from the 1990s and smart technologies in the past decade, it conjures strong images of the future of manufacturing and has convinced Chinese policymakers and manufacturing professionals to pursue this direction.

Under such a supposedly reliable and promising solution from Germany, and increasing pressures to upgrade manufacturing industries, Chinese decision-makers again are taking the easy route by imitating the German method and heading toward the smart paradigm without seriously thinking about our own real problems.

Looking into the root causes of Chinese manufacturing problems, the prioritized strategic tasks for enhancing the industry under Made in China 2025 are seriously debatable.

To a large degree, the strategy has neglected the urgent challenge faced by all Chinese people: Heavy environmental pollution and resource shortages caused by industrialization. Fundamentally, the problems faced by the manufacturing industry are the ones unsolved by industrialized countries. They have all experienced the damage from industrialization, which pollutes first, and cleans up after. The country and even the world would simply be unable to cope with the traditional way of industrialization in China.

More intelligent and efficient manufacturing systems, part of the Industry 4.0 strategy, may speed up the pollution and damage to the environment because the current artificial intelligent systems are not smart enough to improve manufacturing and reduce the waste.

It is obvious that now is the time to start strategic reforms in the economy and related political institutions and systems after 35 years of economic and business reforms. The rising costs and overcapacity issue are far beyond what the industry or technology can control. When we are clearly trapped by Gresham's law (bad money drives out good), Chinese policymakers and intelligent elites skillfully avoid political risk and transfer the ecosystem and institutional problems into technological issues. Again, we are not daring to face the harder challenges, only quietly setting up more time bombs for future generations.

It seems senior and experienced industrialists haven't significantly participated or even been involved in the formation of Made in China 2025. For such critical industrial decision-making, it is unimaginable that real business people have not played a critical role, if not a leading role. The typical Chinese top-down style is definitely the legacy of the centralized planning system.

When will we really recognize who the true value creators are and trust our industrial practitioners?

Compared with Industry 4.0, the Made in China 2025 strategy has its clear strengths and comprehensiveness, including requirements from not only the Industry 4.0 and previous paradigms, but also green manufacturing and industrial restructuring. However, its prioritized tasks are not effectively targeting the root causes of Chinese manufacturing problems.

There is a risky trend that narrows the Chinese manufacturing strategy to Industry 4.0, rather than bravely face Chinese manufacturing's real challenges and work harder to find our own solutions.

Facing two fundamental challenges - labor and environmental issues - in Chinese manufacturing systems, different industries are facing very different pressures based on their intrinsic properties. Industry 4.0 can help some of them, but not significantly.

If we can take the environmental impact of industrial systems more seriously as a strategic priority, China's current and future challenges can be strategically and effectively addressed.

New industrial systems and the new environment-friendly industrialization process could be developed as new Chinese competitive advantages.

The author is research director for the Centre for International Manufacturing at Cambridge University. The views do not necessarily reflect those of China Daily.