Made in China policy gets a guideline boost

Initiative aims to achieve breakthroughs and increase nation's competitiveness

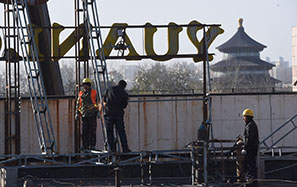

China will further promote its manufacturing sector under 11 guidelines recently released for implementing the Made in China 2025 strategy, which focus on areas such as smart manufacturing, high-end equipment, new materials and branding.

An initiative known as 1+X was finished earlier this month with 11 guidelines published, according to the Ministry of Industry and Information Technology. The "1" stands for Made in China 2025 and "X" refers to guidelines for 11 subsectors, including smart and green manufacturing and innovation of high-end equipment.

More than 20 departments of the State Council, China's Cabinet, participated in the initiative, which aims to achieve breakthroughs in the manufacturing sector and boost the country's competitiveness from a "world factory" to a true manufacturing power, encompassing the process from design to production.

These guidelines aim to be suggestions, not administrative requirements. They endow the market with a bigger role in resource allocation and call for joint efforts by the government, enterprises, research institutes, universities and financial institutions.

Made in China 2025 was first pro-posed by Premier Li Keqiang in his Government Work Report in March 2015. Li has reiterated the plan on many occasions and promoted the upgrading of China's manufacturing sector to be environmentally friendly, cost-effective and high-end.

In a written instruction last year, he called for a lowering of the thresh-old for market access, better allocation of resources and reduced costs for the development of advanced manufacturing industries. He also encouraged the integration of Made in China 2025 with initiatives such as Internet Plus and mass entrepreneurship and innovation, with an emphasis on craftsmanship.

At a State Council executive meeting in April, Li said efforts should be made to boost consumer confidence in domestically made products and promote the international competitiveness of manufacturing industries by improving quality and efficiency.

He also put manufacturing enter-prises at the top of his schedule during each of his inspection tours to regions such as Shanghai, Tianjin and Shenzhen last year.

On a visit to a new Dongfeng Commercial Vehicle Coplant of in Shiyan, Hubei province, in May, the premier encouraged workers to carry for-ward a revolution in quality with a spirit of craftsmanship, and promote the overall upgrading of Chinese products.

"The quality revolution depends on the craftsman's spirit and innovation, and the key is consumer-orient-ed development," he told the workers.

"The strategy of Made in China 2025 and Internet Plus are inseparable, as we must upgrade the manufacturing industry and boost smart manufacturing," Li said at a session of the World Economic Forum in June in Tianjin.

Also in Tianjin, he lifted a "smart" bicycle made of carbon fiber and took it for a test ride at a Flying Pigeon experience store, which features 100-year-old brands.

"I would like to tell Chinese bicycle companies that I support the smart upgrading of the Made in China strategy," he said.

Zhang Jun, chief economist at China Fortune Securities, said China's aging population will lead to a rise in the price of labor and shrinking demand, meaning smart manufacturing is a good way to boost production efficiency and trim costs.

China became the world's biggest manufacturer two years ago but still lags in brand recognition and innovation compared with developed economies, said Xin Guobin, vice-minister of Industry and Information Technology, at an earlier news conference. Smart manufacturing can help tackle challenges when the country faces downward pressure on economic growth and slowing private investment, he added.

huyongqi@chinadaily.com.cn