Textile makers held by a thread

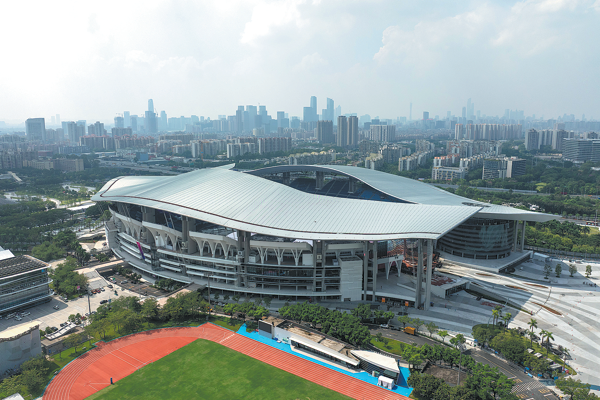

| Above: Jishan Dyeing Plant has adopted advanced printing technology to reduce environmental pollution. Below: A view of East Market of China Textile City in Shaoxing county, Zhejiang province. Photos by Yan Yiqi / China Daily |

County in East China looks to African countries to rebound from downward trend in global orders last year

After almost a year's worth of sluggish export sales in 2012, Huang Yan decided that she could not sit and wait for orders any more. She attends as many exhibitions and fairs as possible to meet new clients. Instead of looking for clients from developed countries, Huang is keen to get in touch with those from developing countries like the ASEAN nations, Russia and Africa. In early January, she was showing clients from Africa around the company in the hope that they might take up the part of orders her European clients failed to take.

Huang is a sales executive at Zhejiang Weizi Textile, which owns two stores in the East Market of China Textile City, the country's largest market for textile products in Shaoxing county, Zhejiang province.

Trade has been slow in 2012, she said, and for small factories like the one she works for, the problem is acute.

"Western clients did not show up, and it is time to explore new markets. Economic growth in developing countries is relatively fast in recent years, so we are considering moving our sales focus to these markets, especially Russia and South Africa," she says.

Her company's idea is a microcosm of the business climate change in Shaoxing.

Shaoxing hosts the densest concentration of textile businesses in the country, with more than 1,000 large-scale textile companies generating a total annual turnover of 153.8 billion yuan ($25 billion). Textiles account for 64.5 percent of production in Shaoxing, said He Jiashun, the county's Party chief.

"Shaoxing's economy is bound by a piece of cloth. A quarter of the world's textile product trading in terms of quantity is done through China Textile City here."

But He says Shaoxing's booming textile industry has faced many hurdles in its efforts to expand.

In 2012, China Textile City's sales revenue was 97.3 billion yuan, up 9.3 percent year-on-year. Revenue has grown an average of 10 percent in recent years, says Shou Lumin, deputy director of the Construction and Management Committee of China Textile City. Its average monthly exports in the first nine months of 2012 were $255 million, an increase of 7.6 percent year-on-year.

While that performance outshines the meager 0.54 percent growth for textile exports nationally, pressure still weighs heavily on Shaoxing.

"We're not going to say shrinking external demand has had no influence on our member companies this year," Shou says. "On the contrary, we have heard many small companies complain about how difficult business is."

Yu Qi is sales manager at Shaoxing Qingwu Textile, one of the small companies that says it has suffered from falling orders. Its products are sold mainly in economically beleaguered Italy, and she says sales revenue from there has been particularly low since the end of 2011. In fact, profits in 2012 may barely be half of what they were in 2011, she says, refusing to elaborate.

"It is not that we don't have orders. In the first half of 2012, the number of orders from foreign clients grew 15 percent compared with the same time 2011. The problem is the prices they offered were too low, so we decided not to take them."

Yu says that if she turns down their orders, the decision may come back to bite the company later on, but if she accepts them, it will hurt the company right now. "The more orders, the more we lose."

Yu says her company has around 30 employees, and to save costs they are encouraged not to turn up for work three or four days a week.

"Our boss says he will not cut numbers, even though at the moment we really do not need so many workers, but we are afraid that if things improve we will end up being short-staffed."

For bigger companies, shrinking overseas demand may not be as serious a problem as it is for smaller companies, but the former face great pressure to modernize the production chain.

One such company is Zhejiang Jinchan Curtain Co, whose chairman, Yang Lairong, says its biggest problem is not shrinking external demand. In fact, with a history of more than 20 years and more than 700 workers, Yang's company performed well in 2012, when sales revenue rose 20 percent year-on-year.

"We have regular customers with whom contracts have been signed long in advance," he says.

Yang says that what preoccupies him most is how to modernize production in this traditionally labor-intensive manufacturing company.

"To be honest, the nature of the textile industry limits the scope of so-called industrial modernization, because the product itself still requires intensive labor and traditional techniques."

Yang says that although his company invested more than 4 million yuan in upgrading the plant in 2011, many qualified workers are still essential to the production process.

"The cost of hiring highly proficient workers is growing all the time, and we have to look for cutting-edge equipment to reduce those costs. But as far as I know there is no technology in China that can come up with the equipment needed to do away with the labor-intensive production that the textile industry requires."

He, the county's Party chief, acknowledges that textile industry modernization is something that cannot be achieved in a day, it is a long-term challenge.

"What Shaoxing's textile industry should essentially be heading for is strong innovative design and branding, but those things cannot relieve the industry of the burden of intensive labor, and that may be a hurdle to further modernization."

Another challenge is how to maintain output while at the same time making an effort to protect the environment. For example, Yang says that some of the textile industry's production processes inevitably produce wastewater.

The local government has stringent environmental protection rules, but it would be too expensive and complex for his company to shoulder the burden of solving this problem, which exists in just one or two links of the whole chain, he says.

"So what we came up with was to outsource our dyeing process, which holds the biggest environmental challenges, to other companies that can handle these problems."

Even as small factories battle to survive shrinking external demand, and the large ones wrestle with the task of modernization, Shaoxing appears confident about the future of its pillar industry.

The autumn edition of the China Keqiao International Textile Expo was held in the city in October 2012, and Shou from China Textile City says local companies' interest in the event was unprecedented. For the first time, there were more than 1,300 stalls at the expo.

Shou says she feels that in her contact with the companies their eagerness to reach out for customers has strengthened.

Yu says the expo is a great opportunity to show products to customers from around the world.

"With the failing European market, our priority is to expand our customer base."

As Shaoxing's textile companies continue to be hit by the slump in orders from the West, there are other markets with great potential, Shou says.

Purchasing delegations from developing countries were more welcomed by stall owners in the textile expo. "People did not focus only on Europe and the US. They were more interested in clients from Africa, ASEAN and the Middle East," Shou says.

A total of 6,232 foreign purchasers attended the expo, and about 15 percent of them were from Africa, according to Shou.

"We do not have specific figures of how much Africa accounts for the whole sales revenue, but as far as I observe, African clients are more frequently seen in recent years than previous ones," she says.

Shou says that as Western recovery continues to be elusive, it is time to turn to emerging markets, with better products and services.

Contact the writers at yanyiqi@chinadaily.com.cn and zhangjianming@chinadaily.com.cn

(China Daily 01/18/2013 page12)

Today's Top News

- Control of precursor chemical exports tightened

- Xi greets Ouattara on reelection as Cote d'Ivoire president

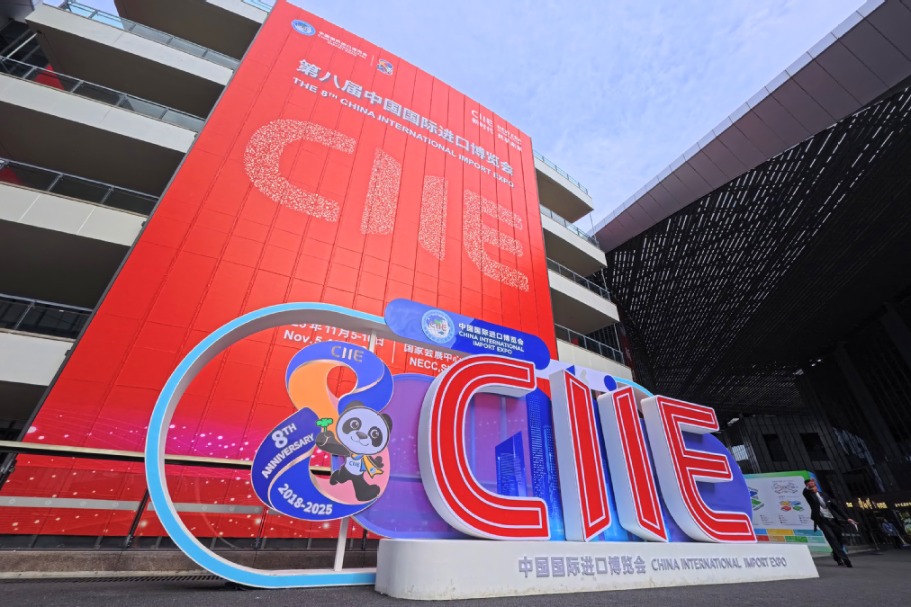

- CIIE displays innovation, global confidence in China

- Nation set to sharpen focus on key sectors

- Nation condemns Japan PM's remarks

- Spanish king on first state visit to China