Ease heavy tax burden to upgrade manufacturing

|

|

A cement plant is seen in Jilin city, Jilin province, Nov 25, 2014. [Photo / IC] |

More than 20 departments?of the State Council, China's cabinet, are pressing ahead with the government's "1+X" initiative. The "1" stands for "Made in China 2025", a road map to enhance the country's manufacturing power, and "X" means guidelines for sectors including smart manufacturing and innovation of high-end equipment. But for the initiative to work extra efforts have to be made to lower tax burden on enterprises, Beijing Youth Daily commented on Thursday:

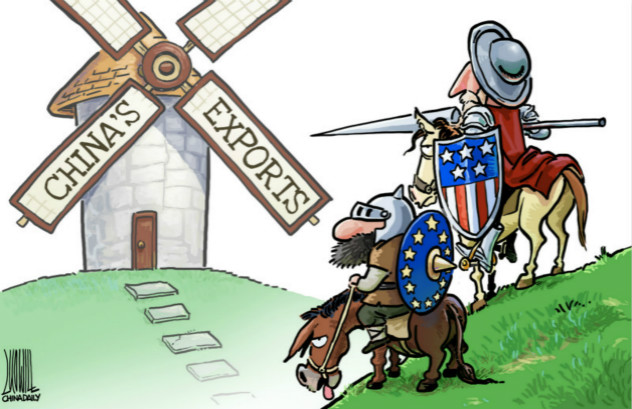

First proposed by Premier Li Keqiang in his government work report in 2015, the "Made in China 2025" guideline was a result of forward-thinking and proactive reading of the changing tides of globalization. Since the 1990s the United States has witnessed an exodus of domestic manufacturers to emerging markets, but it was hit hard by the financial crisis in 2008 and 2009 partly due to its weakened manufacturing.

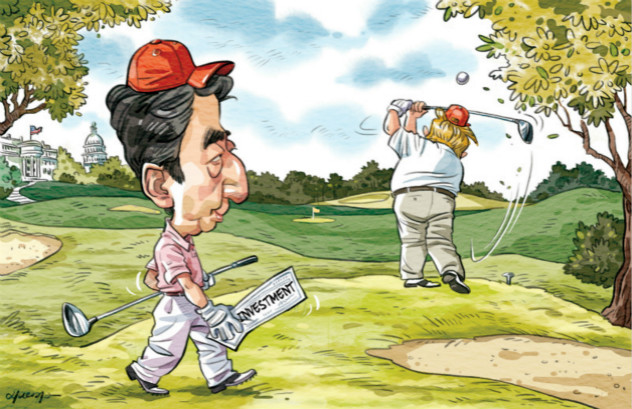

That, to some extent, explains why Donald Trump, the new US president, won unparalleled support from the working class during last year's presidential election. A staple of his campaign efforts was convincing blue-collar workers that he would raise their pay and create more jobs by bringing US manufacturers back from overseas markets.

China can learn a lesson or two from the US' misjudgment and Trump's shortsightedness. The US president did offer to reduce the tax burden and lessen the supervision on enterprises at home, but simply focusing on better employment instead of technological innovation will probably get the country's manufacturing nowhere.

Upgrading its manufacturing industry is exactly what China expects from the "1+X" initiative, which attaches great importance to areas such as smart and green manufacturing, innovation of high-end equipment, and new material. The industrial innovation driven by the Internet Plus, mass entrepreneurship and innovation, and "Made in China 2025", as Li foresaw, has the potential to usher in a "new industrial revolution". That highlights the need to ease the heavy tax burden on Chinese manufacturers, which has hampered the industrial transformation.