Century-old textile mill adopts smart manufacturing practice

While you are most likely familiar with well-known brands like Berberry, H&M, Louis Vuitton and Zara, you may not be aware that much of the quality cotton used by these clothing giants is produced by the Wuxi No1 Cotton Mill.

Talak, the yarn brand of the company, has been registered in 55 countries including the United States, France and Germany, and is a special supplier of many domestic and global brands.

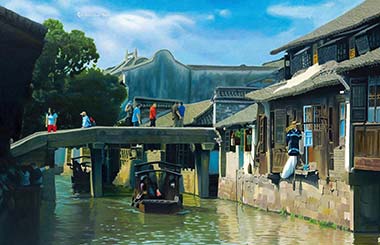

Entering the cotton factory, one would not see many workers, but rows of spinning machines revolving at high speeds. There are only white yarns in the factory, the product will be dyed and woven in other factories upstream.

|

|

White cottons are processed automatically in the “smart” factory of the Wuxi No1 Cotton Mill. [Photo by Miao Jiayu/chinadaily.com.cn] |

As a representative of the national industry, the Wuxi No1 Cotton Mill has undergone many changes since its establishment in 1919. During its first ten years, the company made up 24 percent of the domestic yarn production capacity, and it has always been a leader of the Chinese textile industry.

The enduring prosperity of the company is attributed to its timely transformation in the digital age. According to Zhou Yejun, the company’s chairman of the board, they imported advanced technologies and equipment from foreign countries in 2000, and started to apply information technologies to production and management.

In the “smart” factories, data and the quality of the products, as well as the operation status of the machines, are recorded via a sensor network and a comprehensive information system. Zhou said that only 25 workers are needed per 10,000 spindles, which is one third of the average level.

Thanks to the efforts of information and automation, the company has reduced 7 percent of its energy and electricity consumption, and productivity has risen 10 times higher than before. Zhou expects the number of workers on the assembly line to be cut by a half so that they can invest more in research and development sector.

Edited by Zack