High-tech manufacturing in spotlight

Further efforts should be made to optimize the financing environment for China's high-tech manufacturing sector, said Li Dongsheng, founder and chairman of Chinese consumer electronics maker TCL Technology Group Corp.

Li, who is a deputy to the 14th National People's Congress, China's top legislature, also called for Chinese high-tech manufacturing enterprises to increase the number of application scenarios for cutting-edge artificial intelligence technology.

He said that China's high-tech manufacturing sector has become a cornerstone in promoting high-quality economic growth, and Chinese enterprises are catching up with leading global tech companies in fields such as integrated circuit manufacturing and semiconductor display.

China's high-tech manufacturing is a heavy-asset industry requiring large amounts of capital input.

However, manufacturing enterprises currently have some difficulties in terms of financing, Li said, highlighting the importance of increasing support for leading high-tech manufacturing companies to ensure that they gain a competitive edge amid fierce international competition.

Li suggested providing such enterprises with innovative services and assistance from the capital market, moderately easing equity financing restrictions, and improving the predictability of capital market financing.

China ranked as the world's largest manufacturer for the 15th consecutive year in 2024, and its manufacturing output accounted for about 30 percent of the global total, according to the Ministry of Industry and Information Technology.

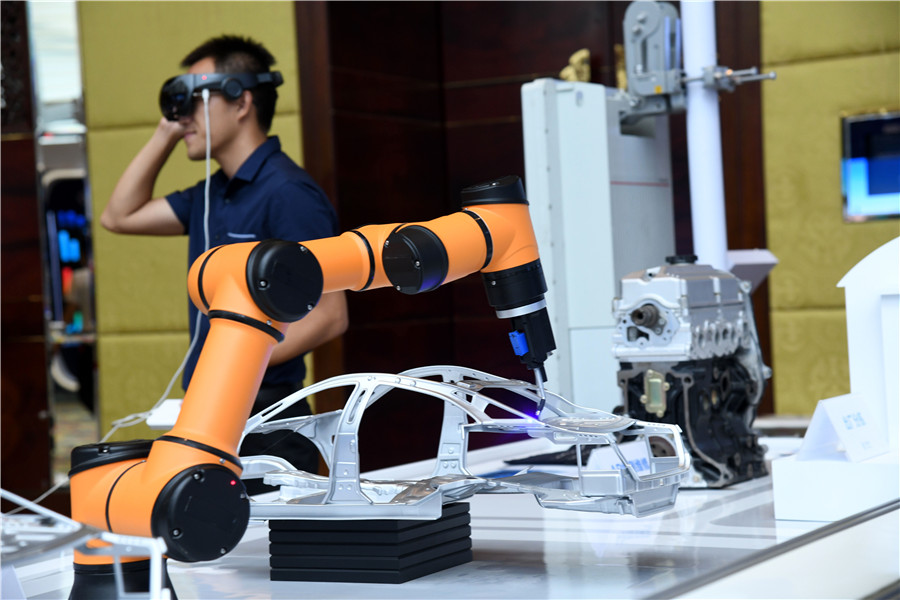

As fast-developing generative AI technology is spearheading a new round of industrial transformation and upgrading, Li said that TCL has applied AI technology in intelligent transformation and the upgrading of its manufacturing supply chain, as well as product research and development in order to improve production efficiency.

"We established an AI research and development center in Poland in 2018. Prior to that, we set up an R&D center in the United States in 2011. As a manufacturing enterprise, we will focus more on the application of AI," Li said.

So far, TCL has established 46 R&D centers and 38 manufacturing centers around the world, with operations in more than 160 countries and regions.

He emphasized that Chinese enterprises' globalization is of vital importance in boosting the sustainable development of the Chinese economy, adding that globalization is a long-term strategy for TCL, and that domestic high-tech manufacturers should accelerate their expansion in overseas markets.

Against the backdrop of changes in global trade rules and reconstruction of the global economic pattern in recent years, Li said that Chinese enterprises should optimize their presence in global industrial and supply chains, and speed up localizing production and operations, in order to enhance their competitiveness in the manufacturing sector globally.

He also highlighted the significance of technological innovation and capital input in bolstering the development of high-tech manufacturing.

Luo Zhongwei, a researcher at the Chinese Academy of Social Sciences' Institute of Industrial Economics, said that China's high-tech manufacturing sector is playing an increasingly pivotal role in bolstering technological innovation, safeguarding the stability of industrial and supply chains, and helping the country gain competitive advantages on the global stage.

He added that it is crucial to push the manufacturing sector toward higher-end, smarter and greener production through the adoption of new-generation information technologies, including AI, 5G, big data and the internet of things.

fanfeifei@chinadaily.com.cn

- Beijing launches program to foster international entrepreneurship

- China starts construction of water diversion project to quench thirst of metropolis

- China's Greater Bay Area builds world-class city cluster through connectivity, innovation

- Guangzhou forestry and fruit expo to showcase Xinjiang's specialty products

- Xi's special envoy to attend inauguration of Bolivia's president

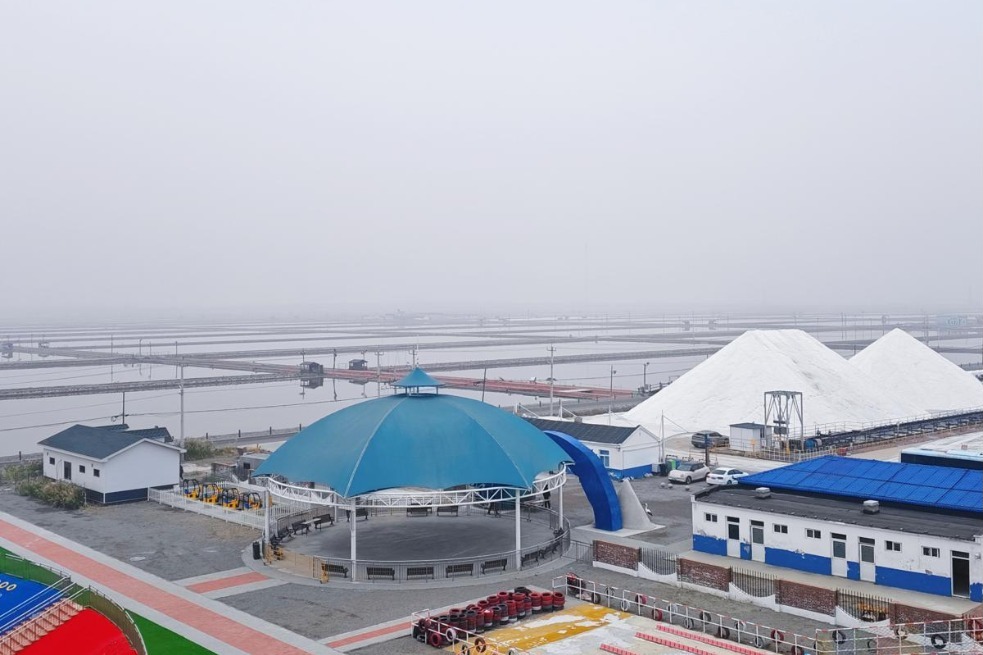

- Tianjin's Hangu Salt Field marks 1,100th anniversary