Tianjin data center's steel will to save energy

Steelmaker transforms itself from heavy industry workhorse to digital dynamo

Despite making the extraordinary decision to pivot from being a heavy industry player to a digital industry heavyweight in 2017, Tianjin GiantDC Technology Co, located in Tianjin's Beichen district, has been able to carry over parallels from these two seemingly diametrically opposed businesses.

Taking the leap from making steel to storing data was not as crazy as it sounds in the context of China's large-scale push to move away from polluting heavy industries and the promotion of the digital economy, as demonstrated by the national dual carbon goals and Digital China strategy.

"Saving energy was the key to survival for steel companies. Today, the concept of energy management has become a key part of our way of thinking," said Meng Qingli, director of energy development at GiantDC. "After transforming into a data center, this awareness has become an even more valuable asset."

In January 2017, coal and steel capacity reduction plans were rolled out across China.

Tianjin stepped up its efforts to implement the reform, cutting steelmaking capacity by 1.8 million metric tons that year.

GiantDC, known back then as Tianjin Tianzhong Jiangtian Heavy Industry Co, also responded, shutting down its furnaces and completely transferring its business to a new industry.

"Data centers are an emerging industry," said Meng. "In the early stages, the focus was more on technological breakthroughs rather than energy conservation and emission reduction.

"But now, placing emphasis on energy efficiency has become one of our core competitive advantages, and it has gradually helped raise awareness of energy conservation across the industry."

For data centers, cooling equipment is one of the largest sources of energy consumption.

GiantDC has adopted advanced indirect evaporative cooling technology.

Now widely used in the data center industry as an energy-efficient cooling method, this technology was still a cutting-edge innovation eight years ago, Meng said, adding that it can significantly reduce energy consumption while ensuring effective temperature control.

"We make use of cool outdoor air, which is first filtered and further cooled, then passed through a heat exchange device to transfer heat with the return air from indoors, thereby cooling the equipment," he said. This process is like adding a "heat exchange core" between walls — lowering the temperature while keeping the indoor air clean and stable.

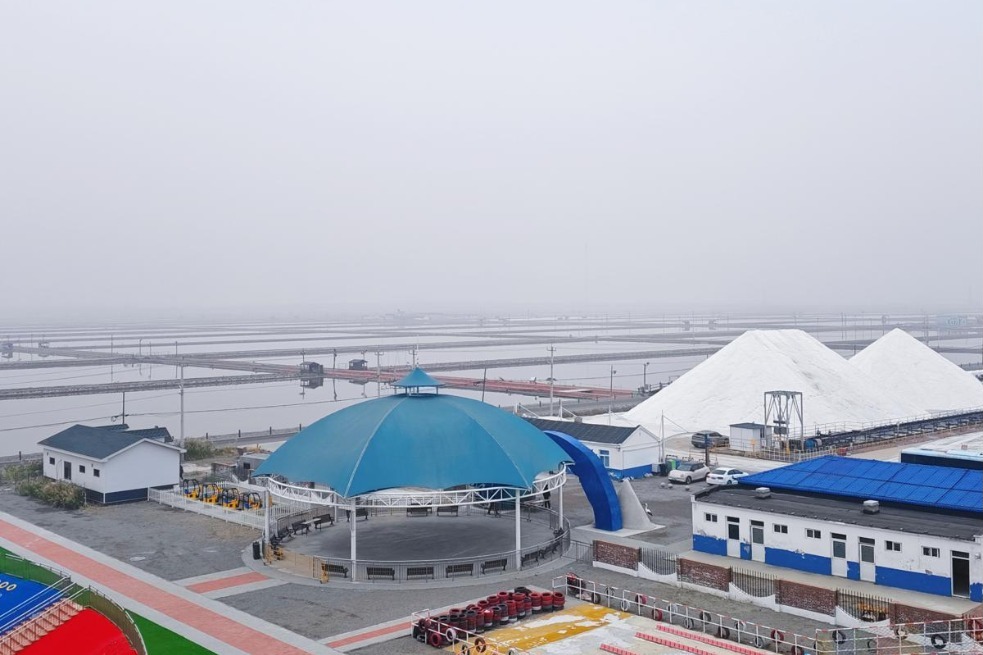

Green park

Beyond the cooling system, many features across the industrial park where GiantDC is located reflect a green, low-carbon philosophy.

South-facing walls and all non-equipment roof areas are covered with photovoltaic panels to supply clean electricity. Less than two kilometers away, a fishery-solar hybrid project is underway, where fish, shrimp, and crabs are cultivated in the water with solar panels installed above to provide shade, creating a symbiotic system of ecology and energy.

The park also employs smart design, with cooling water pipes kept as straight as possible to reduce energy loss during circulation, power supply lines replanned to minimize transmission losses, and a lighting system optimized to avoid wasted electricity.

According to Meng, these energy-saving measures have brought the park's overall power usage effectiveness index down to below 1.22. PUE is a key metric for evaluating a data center's energy efficiency — the lower the number, the higher the efficiency. Most domestic data centers have PUE values of around 1.5.

"Green energy-saving principles run through the entire process," Meng said. "From the very start of planning and construction, this awareness has been deeply embedded at every stage. The results we see today are not the work of a single piece of equipment, but the success of systematic innovation."

- CNS Fujian's home base is the Sanya Military Port, the Chinese Navy says

- Xi urges deepening reform, opening-up during Guangdong inspection tour

- Xi attends carrier's commissioning

- Xi inspects Meizhou in South China's Guangdong

- Senior Xi'an official facing probe by China's anti-corruption watchdogs

- Philippines risks creating trouble for itself: China's defense ministry