Danish toy maker hails green efforts of Beijing

Danish toy maker LEGO Group sees China as a key market in achieving its sustainability ambitions and recognizes the proactive role that its factory in Jiaxing, East China's Zhejiang province, has played in the green transition, said Annette Stube, chief sustainability officer at LEGO Group.

"China is incredibly important for us. We have a long-term commitment there. There are 200 million children in China, and as a company, we want to provide learning-through-play opportunities for children all over the world, including China," said Stube.

Founded in 1932, the family-owned business has established a global presence, with its products sold in more than 120 markets. With 450 stores now operational in China, the company has been stepping up its commitment there, for example, by expanding the manufacturing capacity at its Jiaxing factory and opening the LEGOLAND Shanghai Resort this July.

China stands not only as a major consumer market, Stube highlighted, but also as a testing ground for the group's innovative sustainable practices, as China boasts renewable energy technologies, and a policy commitment demonstrated by its dual carbon goals of peaking carbon dioxide emissions before 2030 and achieving carbon neutrality before 2060.

Similar targets

China and the LEGO Group share similar climate targets, Stube noted, as the company pledges to reduce absolute greenhouse gas emissions by 37 percent by 2032, compared to 2019, and to achieve net-zero greenhouse gas emissions by 2050. "I think that is not a coincidence because this is what science tells us needs to be done," she said.

Stube also said the factory has been at the forefront of implementing the group's global sustainability ambitions through local, tailored solutions, offering the world valuable lessons from the "China experience".

Opened in 2016, the Jiaxing factory is the LEGO Group's first factory in Asia and its fifth manufacturing site globally. It spans bout 315,000 square meters and produces between 70 and 80 percent of all LEGO products sold in Asia.

The factory always has a strong focus on sustainability, the LEGO Group said. For example, in October, the plant completed the full transition of its existing packaging lines from plastic to paper-based materials, after beginning the process in 2023 as part of the group's global initiative to move toward sustainable packaging.

"It is a big transition," Stube said, as she pointed out that the transition is not a straightforward swap of one material for another, but a complex changeover that involves considerable sensitivity, such as machinery upgrades, production line adjustments, and employees adapting to new ways of packaging, all requiring substantial investment.

In terms of reducing emissions from its production sites, the Jiaxing factory installed a new system in 2024 to capture and reuse heat from chillers, reducing natural gas consumption by 50 percent. The group said the system has been "so successful" that it is now being extended to other parts of the factory, with the aim of completely phasing out natural gas.

In August, the Jiaxing site also signed a power purchase agreement to source electricity from renewable energy, aiming to run on 100 percent renewable energy.

When asked why the Jiaxing factory has stood out in advancing sustainability efforts, Stube said, "It is the local efforts — the people at the factory who are really driving these efforts — as well as the global management (decision) that chooses where we want to push these initiatives first."

"China is such an important market to us … It's a natural choice to start there," she said.

Jiang Yi, head of communications at LEGO Group China, said China is the only regional market where the company has a dedicated sustainability communications role within its global communications team.

"This also reflects how much we value the role of Chinese market in sustainability, which mirrors the Chinese government's level of commitment and investment in this area."

A bigger picture

The Jiaxing factory is just one of the pieces in the larger puzzle of the group's sustainability strategy.

The company said it strives to play its part in helping build a sustainable future, because it wants children to inherit a healthy planet and is "determined" to make that happen, according to its latest sustainability statement released in March.

In 2024, the group increased its overall investments in environmental sustainability by 68 percent, compared to spending in 2023 and nearly three times the spending from 2022.

One thing that really sets the group apart from other businesses, Stube said, is the unwavering support of the Christiansen family, the company's founders who have been "sticky" in pursuing the sustainability ambitions — even absorbing the costs themselves to ensure that related investments are not passed on to consumers.

Major steps to minimize the company's environmental impact, beyond the above-mentioned use of recycled packaging and solutions to cut carbon emissions from brick production, include giving LEGO bricks a long lifespan, giving a second life to discarded bricks, and experimenting with sustainable materials to replace plastics.

The current material used for the classic LEGO bricks is acrylonitrile butadiene styrene, or ABS, a petroleum-based plastic, known for its toughness, impact resistance and ease of processing.

The commonly accepted rule of thumb is that it takes about 2 kilograms of fossil fuel to produce 1 kg of plastic, including ABS.

ABS elements make up around 85 percent of the resin used in LEGO bricks.

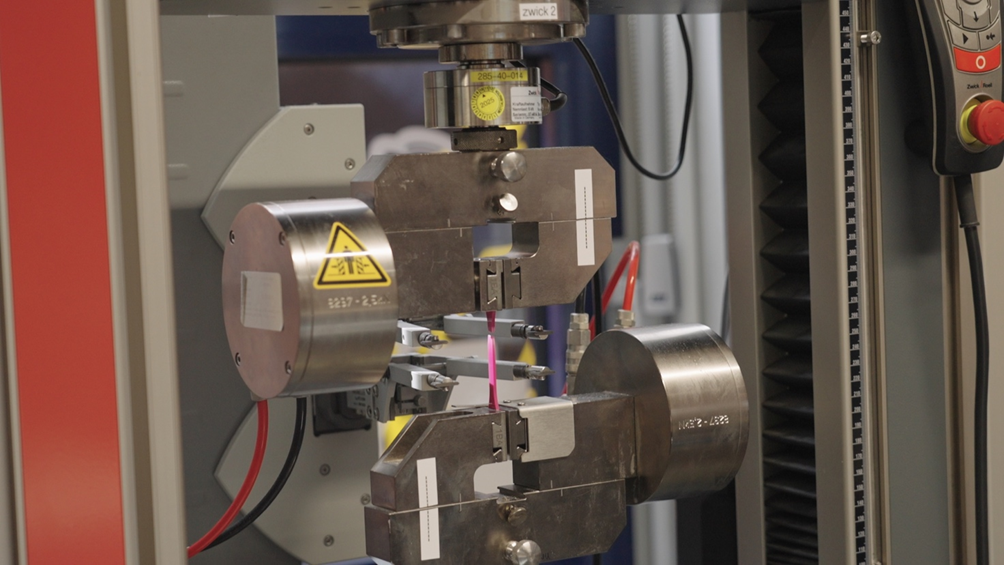

Stube said the company has tested more than 600 alternative materials, some of which have been validated for manufacturing of certain components.

For example, bio-polyethylene, or bio-PE, which is made from sugarcane, has been used since 2018 to produce flexible parts, including LEGO flowers, botanical elements, and minifigure accessories – amounting to more than 200 different items.

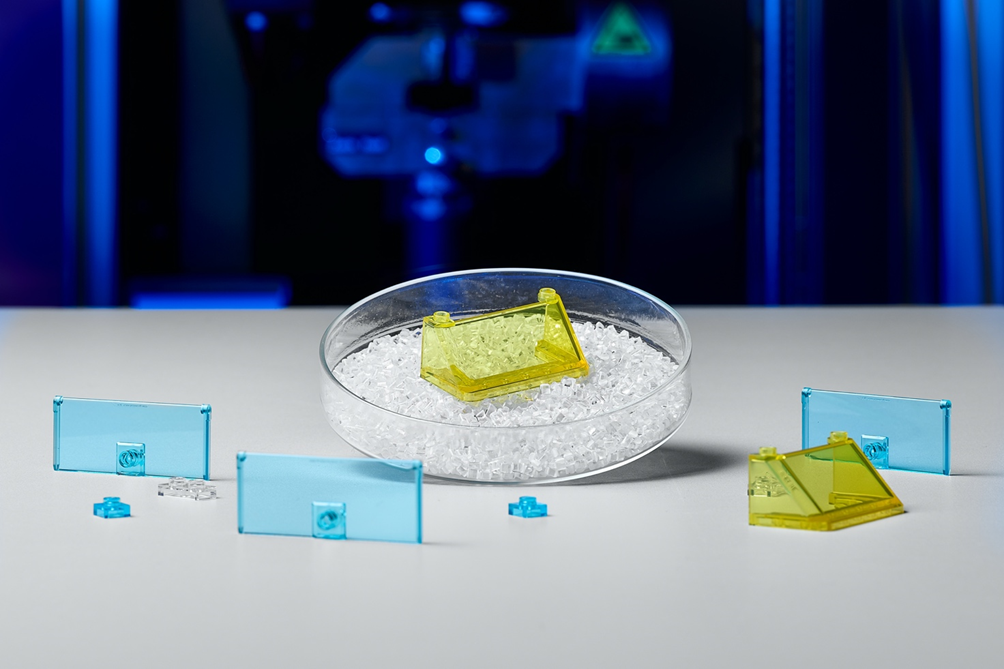

And artificial marble kitchen worktops, or arMABS, have been recycled since 2024 and used to create more than 900 transparent elements, including lightsabers, windscreens, and windows.

E-methanol, which is set to be introduced next year, represents one of the latest innovations. Scientists combine renewable hydrogen with captured carbon dioxide to create this renewable liquid fuel, which can then be converted into a more sustainable form of plastic for making robust, rigid LEGO elements, said a material scientist at the LEGO Lab, where a variety of recyclable and renewable materials are developed and tested.

Some materials that showed great potential from a sustainability perspective failed during testing due to quality, safety, or durability concerns, Stube said. He said if bricks do not meet those requirements, they could undermine sustainability efforts by becoming more disposable products.

"We want the bricks to have a long life. It is not the stuff we buy today, use for a short time, and then is being thrown away. Kids grow, but our toys should be something that can be used over and over again," she said.

At this moment, there may be no one-size-fits-all material to replace ABS.

Stube said the company is aware that plastic is ultimately not environmentally friendly and is looking into supply chains capable of recycling ABS. However, these supply chains have yet to reach scale.

The interim measure is to make each ABS part more sustainable by incorporating more bio-based and recycled material, an approach known as mass balance, Stube said. Currently, 50 percent of the resin purchased to make LEGO bricks is certified through mass balance principles.

The company is aiming to make all LEGO bricks from sustainable materials by 2032.

"Sometimes we succeed, sometimes we fail, and that's the nature of innovation," Stube said. "For the LEGO Group, we are still completely committed the same way as we've been for many years. So, whatever is going on in the world has not affected our commitments. They remain the same."

Many LEGO elements have been creatively reused. In the botanical collection displayed at the LEGO Idea House in Billund, the body of a pink frog piece serves as a flower's stamen, while a car hood element is transformed into a rose petal. [Zheng Wanyin/China Daily]

zhengwanyin@mail.chinadailyuk.com